Enhancing Efficiency and Safety with Proximity Switches in Manufacturing Processes

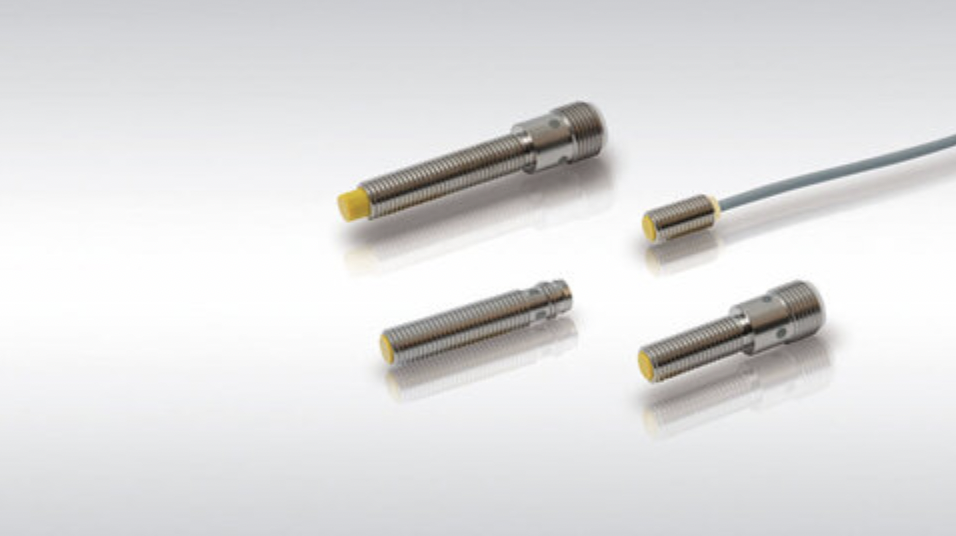

Proximity switches, also referred to as proximity sensors, play a vital role in enhancing efficiency and safety in manufacturing processes. These devices are used in a wide range of industries to detect the presence or absence of objects without physical contact, enabling automation and improving operational effectiveness. Whether you are a proximity sensor manufacturer or a manufacturing professional seeking to optimize your processes, this article will explore how proximity switches contribute to efficiency and safety in manufacturing.

Automation and Process Optimization

Proximity switches are integral to automation in manufacturing processes. By detecting the presence or absence of objects, these switches act as triggers for various actions, such as initiating assembly operations, activating conveyors, or controlling robotic movements. This automation reduces the reliance on manual intervention, increasing efficiency, and minimizing human error. With the ability to detect objects quickly and accurately, proximity switches enable streamlined and optimized manufacturing processes.

Reducing Downtime and Enhancing Productivity

Downtime in manufacturing can be costly and disrupt the production flow. Proximity switches help reduce downtime by providing reliable object detection. By detecting jams, blockages, or other issues in real-time, proximity switches can trigger alarms, halt machinery, or divert operations to resolve the problem promptly. With rapid detection and response, production downtime is minimized, leading to enhanced productivity and increased throughput in manufacturing operations.

Ensuring Worker Safety

Worker safety is of paramount importance in manufacturing environments. Proximity switches contribute to safety by preventing accidents and ensuring compliance with safety regulations. These switches can be used to detect the presence of personnel in hazardous areas, initiating safety measures such as automatic machine shutdown or warning signals. By offering reliable object detection capabilities, proximity switches help create a safe working environment and mitigate potential risks to workers.

Detecting Misalignment and Positioning Issues

Proximity switches are valuable tools for detecting misalignment and positioning issues in manufacturing processes. For example, in assembly line operations, proximity switches can verify that components are correctly aligned before initiating the next step. By detecting deviations or misalignments, these switches prevent errors, reduce rework, and save valuable production time. Manufacturers rely on proximity switches to validate the proper positioning of materials, ensuring accurate assembly and minimizing the risk of faulty or defective products.

Enhancing Equipment Longevity and Maintenance

Proximity switches aid in extending the longevity of manufacturing equipment by reducing wear and tear. By accurately detecting the presence of objects, these switches can prevent unnecessary equipment cycling or operation. For example, in conveyor systems, proximity switches ensure that equipment is activated only when an object is present, reducing unnecessary movement and extending the lifespan of motors or mechanical parts. Additionally, proximity switches contribute to proactive maintenance by providing real-time data on equipment status, triggering alerts when maintenance is required, and enabling predictive maintenance practices.

Collaborating with a Proximity Sensor Manufacturer

Effective utilization of proximity switches in manufacturing processes often involves collaboration with a proximity sensor manufacturer. Proximity sensor manufacturers possess specialized knowledge and expertise in designing and producing high-quality proximity switches for various industries. They can provide guidance on selecting the right proximity switches for specific applications, offer customization options, and ensure compliance with industry standards and regulations. By collaborating with a proximity sensor manufacturer, manufacturers gain access to cutting-edge technology and solutions tailored to their unique manufacturing needs.

Conclusion

Proximity switches have become indispensable devices in enhancing efficiency and safety in manufacturing processes. By enabling automation, reducing downtime, ensuring worker safety, detecting misalignment, and supporting equipment longevity, proximity switches contribute significantly to optimizing manufacturing operations. Collaborating with a proximity sensor manufacturer provides manufacturers with access to advanced solutions and expertise, ensuring the selection of suitable proximity switches for specific applications. With the integration of proximity switches, manufacturers can unlock higher efficiency, enhanced productivity, and improved workplace safety in their manufacturing processes.

Passionate Writer, Blogger and Amazon Affiliate Expert since 2014.